Fynspray pumps are manufactured from the highest quality materials and are practically maintenance free. However, as with most moving parts, the pump will operate more smoothly and efficiently with a regular maintenance check. This procedure is described below.

LOSS OF (OR POOR) SUCTION:

This can be caused by foreign matter in the valves preventing the balls from seating.

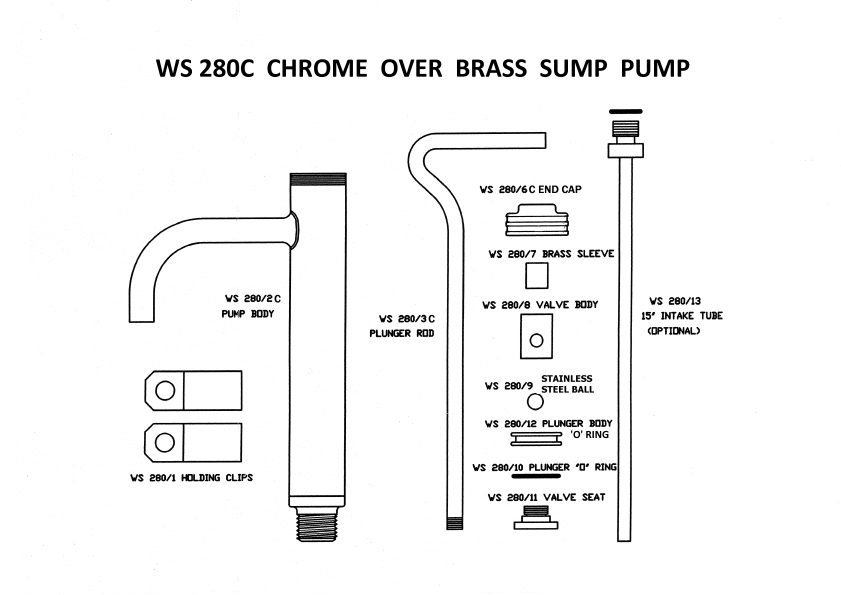

A badly worn plunger ‘O’ ring (WS 280/10) will cause loss of suction.

- If mounted with a permanent intake, disconnect this.

- Visually check the ball valve in the bottom of the pump body. If the valve is blocked, clean it out and flush with water. If the valve is sticking lift it off its seat several times with a pencil. DO NOT USE A SHARP OBJECT THAT WILL SCRATCH THE BALL.

- Unscrew the end cap (WS 280/6) from the pump body (WS 280/2). The end cap is sealed to the pump body with a sealant. To break the seal run under hot water and tap the end cap with a plastic or wooden hammer. Place the end cap in a vice with just enough pressure to hold it tight and unscrew the pump body (barrel) by hand. WARNING: DO NOT HOLD THE PUMP BARREL IN A VICE OR PLIERS OF ANY TYPE AS THIS WILL DAMAGE THE BARREL.

- Check the plunger valve (WS 280/8) & ball (WS 280/9).

- Check the plunger ‘O’ ring (WS 280/10) for distortion or damage. Replace if necessary using a heat resistant ‘O’ ring as supplied in the Service Kitset (WS 280/14).

- Reassemble the pump, using a little joint sealant on the end cap thread.

- Test the pump before re-installing.